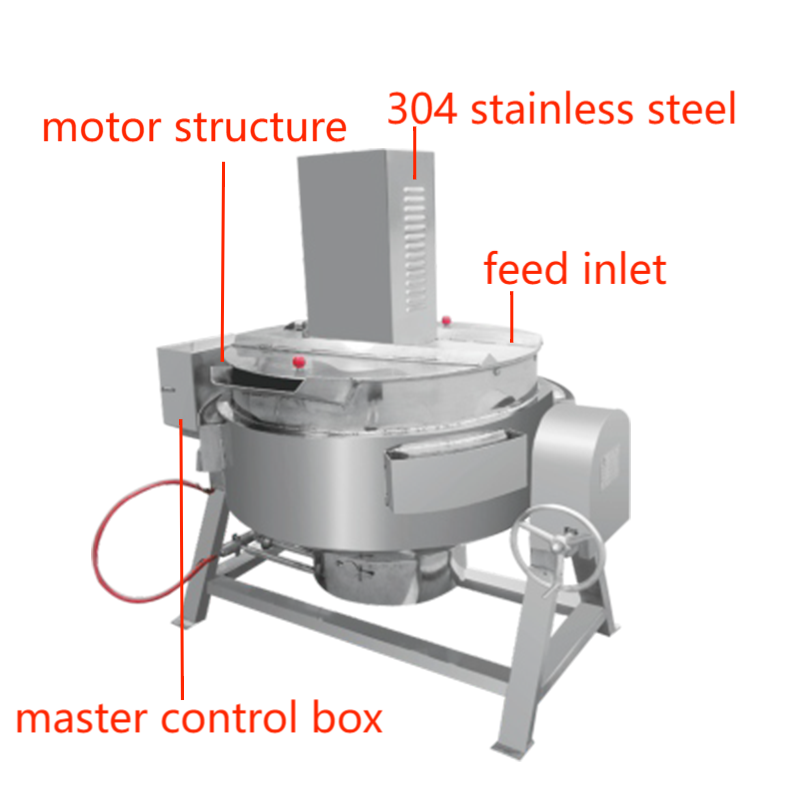

Large Roller Stir-Frying Machine

The electromagnetic direct heating method is adopted, the heating inside the drum is uniform, there is no dead Angle, the thermal efficiency is higher and the operating cost is lower.

- Henco

- Shandong China

- Within 15 Days

- Factory Direct Supply

- Information

- Video

Product Introduction

1. The equipment uses electromagnetic direct heating to make the cylinder heating faster and more uniform. The cylinder body rotates so that the material is stirred without dead angle and heated evenly.

2. Because of the direct heating of the cylinder and the direct contact between the cylinder and the material to avoid heat loss, the equipment has higher thermal efficiency, more energy-saving and lower operating cost.

3. The control system for intelligent operating system is easy to learn and understand, simple to operate, simple to install equipment as a whole, compact structure, small occupied area, reduce matching costs, and has the advantages of rapid smelting, high efficiency and energy saving, easy temperature control, low pollution, and meeting the requirements of national environmental protection.

4. The energy source of this equipment is electromagnetic heating without pollution, dust and harmful gases, so it can significantly improve the working environment and health conditions.

5. Use safety, electromagnetic heating equipment adopts induction heating, no open fire, no explosion, no fire danger;

6. Green environmental protection, the use of electromagnetic heating equipment without waste gas, waste residue and noise pollution, clean and convenient. Compared with fuel gas heating, heating cost can be saved by more than 50%, preheating time can be shortened by 1/5, resistance heating wire heating can be saved by more than 30%, preheating time can be shortened by 1/3. And has been well promoted at home and abroad!

Product Parameters

Model: | LC-600 |

Pot type: | 600*500mm |

Rotating Power (KW): | 1.1 |

Flip and Stir(Kw): | 0.75 Dual core RV |

Frequency converter(Kw): | 1.5 |

Inner roller : | Stainless steel 304 |

Outer roller : | Stainless steel 304 |

Inner roller thickness : | 6mm |

Outer roller thickness : | 3mm |

Heating power (kw): | 25 |

Heating resource : | Electromagnetic heating |

Discharge : | Automatic |

Voltage: | 380V |

Capacity (kg): | 8-10 |

Model: | LC-700 |

Pot type: | 700*600mm |

Rotating Power (KW): | 1.1 |

Flip and Stir(Kw): | 0.75 Dual core RV |

Frequency converter(Kw): | 1.5 |

Inner roller : | Stainless steel 304 |

Outer roller: | Stainless steel 304 |

Inner roller thickness: | 6mm |

Outer roller thickness: | 3mm |

Heating power (kw): | 30 |

Heating resource: | Electromagnetic heating |

Discharge: | Automatic |

Voltage : | 380V |

Capacity (kg): | 30-40 |

Model: | LC-900 |

Pot type: | 900*800mm |

Rotating Power (KW): | 1.5 |

Flip and Stir(Kw): | 0.75 Dual core RV |

Frequency converter(Kw): | 1.5 |

Inner roller : | Stainless steel 304 |

Outer roller: | Stainless steel 304 |

Inner roller thickness: | 6mm |

Outer roller thickness: | 3mm |

Heating power (kw): | 40 |

Heating resource: | Electromagnetic heating |

Discharge: | Automatic |

Voltage : | 380V |

Capacity (kg): | 70-80 |

Product features and applications

Product details Multi-directional display