Breakthrough in Food Machinery Processing Lines in 2024

2024-02-03 09:20Breakthrough in Food Machinery Processing Lines in 2024

In 2024, the world of food processing witnessed a groundbreaking development in machinery technology. A new generation of food processing lines, designed with innovative features, marked a significant milestone in enhancing production efficiency, product quality, and operational safety.

At the heart of these advancements was the use of advanced alloy materials and unique manufacturing techniques. This not only ensured a longer lifespan for the equipment but also provided greater reliability and durability, reducing the frequency of maintenance and repairs.

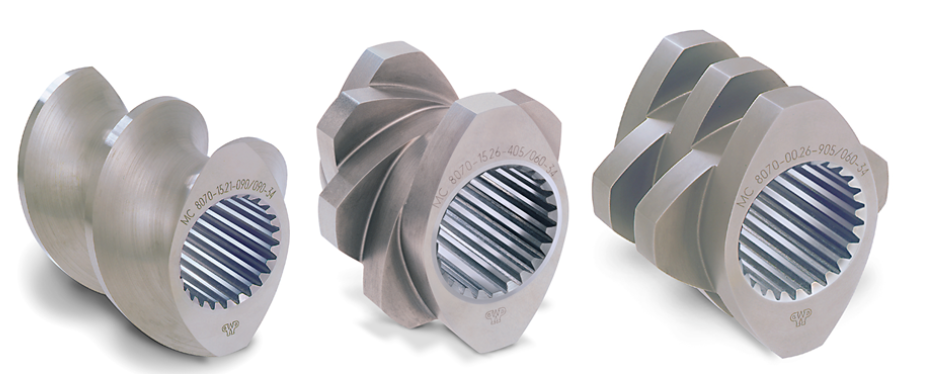

One of the standout features was the introduction of the screw combination. This design enabled the processing of a wider range of raw materials, making the lines suitable for a diverse array of products. It provided greater flexibility and adaptability, meeting the demands of various production requirements.

The feeding system on these new lines employed a dual-screw direct feeding method. This innovative design ensured even and consistent material delivery, reducing potential bottlenecks and enhancing overall production output. It provided greater precision and accuracy, ensuring efficient processing of materials.

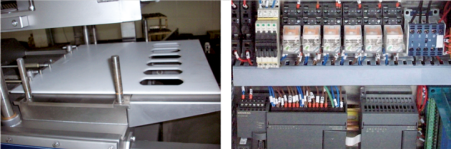

Another key development was the integration of a linear bearing knife adjustment system. This system provided precise and intuitive control over knife settings, enabling operators to make quick and easy adjustments. It facilitated greater accuracy in cutting and slicing operations, enhancing product quality and consistency.

A noteworthy aspect was the self-cleaning functionality built into the machinery. This feature simplified daily operations and maintenance, reducing downtime and making the lines more efficient. It eliminated the need for manual cleaning and kept the equipment in top condition, ensuring consistent performance over time.

In addition, the state-of-the-art temperature control system provided precise temperature management. It featured visual automation, providing operators with a clear and intuitive interface for temperature monitoring and control. This enabled them to adjust temperatures quickly and easily, ensuring optimal product quality and preventing potential temperature-related issues.

These advancements in food processing machinery have opened new opportunities for food manufacturers. Adopting these new processing lines has enabled them to increase production output, improve product quality, enhance operational efficiency, and expand their product portfolios. It has also positioned them to compete in today's demanding market, meeting the growing demand for high-quality and diverse food products.

As the food processing industry continues to evolve, it is expected that further technological advancements will be made in areas such as production efficiency, product quality, operational safety, and sustainability. With ongoing research and development efforts, the future of food processing looks promising, paving the way for even more groundbreaking technological advancements in the years to come.